ISO 9001 Certification: The importance of the process approach

Since Update of ISO 9001 Certification in 2000, the procedure approach has been an imperative guideline

behind the way a Quality Management System (QMS) functions. Utilizing this

methodology, an organization is entrusted to distinguish the procedures inside

the QMS, characterize how the procedures work, and furthermore recognize how

these individual procedures communicate with one another. By appropriately

distinguishing the procedures, and the normal outcomes, it is less demanding to

screen and control how the procedures are working.

Additionally, by

concentrating on the procedures, it is simpler for your association to chip

away at persistent improvement. By separating the general QMS into littler

procedures, it is a lot less demanding to recognize zones for development,

survey the danger of executing changes, and approve that the progressions have

brought about upgrades to the procedure. Since progress is additionally one of

the quality administration standards, and one of the fundamental motivations to

execute a QMS, this is a critical part of actualizing the procedure approach.

What is involved in

identifying the processes?

Begin by walking through your QMS procedure for making

and conveying your item or administration from the earliest starting point

(e.g., showcasing or deals) and experience until the end (e.g., conveyance or after

conveyance administration). What are the majority of the sub-forms that are

required to get from the earliest starting point as far as possible? After

these sub-forms are distinguished, ensure you additionally recognize the

supporting procedures that enable this to occur (e.g., archive and record

control forms).

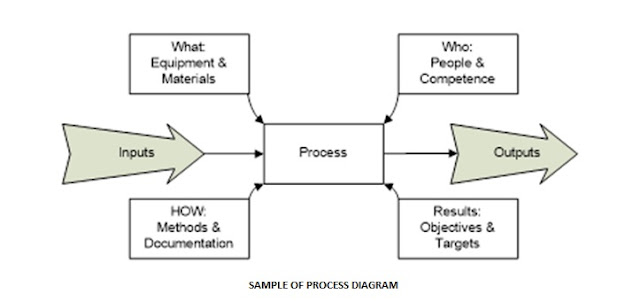

Next, take a each at

every one of these littler procedures as an independent element with the goal

that you can recognize the sources of info, what is done, who does it, how it

is done, the outcomes expected, and the procedure yields. One apparatus for

this is the "turtle chart" presented underneath, which is one state

of mind about how a procedure is organized. This isn't the main procedure

device accessible, yet it is usually utilized and effectively comprehended. It

is likewise a smart thought to have a procedure proprietor who comprehends the

procedure and is in charge of the procedure results.

When you have

distinguished the procedure, you would then be able to pick up the advantages

of control, observing, and improvement for each procedure as referenced

previously. Along these lines, the procedure proprietor can tell if the

procedure is working legitimately, and if any progressions made have brought

about enhancements.

What often gets missed when

implementing the process approach?

A standout amongst the frequently overlooked, and

critical, components of the procedure approach is to give close consideration

to the connections between procedures. Once in a while a procedure proprietor

can turn out to be excessively centered around the upkeep and improvement of

their own procedure, and they can neglect to likewise focus on how their

procedure collaborates with different procedures. Truth be told, a ton can be

picked up from investigating how your procedures collaborate in the QMS.

As was talked about in How connects between procedures

can improve level of value, there are two fundamental advantages to putting

some attention on the associations between procedures. To begin with, rolling

out an improvement to improve one procedure may not be the best thought whether

it causes issues in different regions that exceed the improvement. This must be

found in the event that you take a gander at how each procedure collaborates

with others..

Furthermore, it is essential to know how the yields of

your procedure are utilized. The principle reason is that seeing how the yields

are utilized will enable you to concentrate on how you improve your result.

Similarly vital is the capacity to recognize a result that isn't required. For

instance, in the event that you are making a report as a procedure result, and

this report isn't utilized by you as procedure proprietor, (for example, an

observing apparatus), not required as a record of the procedure, and isn't

utilized by any other individual in the association, at that point the push to

make this report is squandered and the assets can be utilized all the more

proficiently somewhere else.

The process approach: To maintain

and improve

By utilizing the procedure way to deal with characterize,

comprehend, and control your QMS forms, you will find that you can more readily

screen how the procedure is performing, recognize and actualize enhancements in

the procedures, and realize that you are keeping up those upgrades after

changes are made. This is the most straightforward approach to do this, and on

the grounds that observing and improving your QMS would one say one is of the

primary reasons you execute a QMS as indicated by the ISO 9001 Certification necessities,

wouldn't you need these procedures to be as simple as could be expected under

the circumstances?

Comments

Post a Comment